DTF (Direct-to-Fabric) transfer technology offers a versatile method for custom apparel design, supporting various fabric types and printing techniques for high-quality, long-lasting prints. To maximize its benefits, strategically apply treatments based on skin type and specific needs, ensuring proper preparation and consistent use. Case studies demonstrate the real-world success of DTF transfers in garment customization, with custom sheets and heat press machines enabling intricate detailing and vibrant colors. Businesses leverage this technology for personalized apparel production, from small batches to large orders, while maintaining exceptional quality and customer satisfaction.

Discover the transformative power of DTF (Direct to Final) transfer benefits and how they can significantly enhance your processes and outcomes. This comprehensive guide explores practical strategies for maximizing these advantages, from understanding their fundamental potential to implementing case-proven best practices. By delving into real-world examples, you’ll learn actionable techniques to achieve exceptional results in various applications of DTF Transfer Benefits.

- Understanding DTF Transfer Benefits: Unlocking Potential

- Strategies for Optimal Application: Achieving Desired Results

- Case Studies: Real-World Success Stories and Best Practices

Understanding DTF Transfer Benefits: Unlocking Potential

Understanding DTF Transfer Benefits: Unlocking Potential

DTF (Direct-to-Fabric) transfer technology offers a multitude of advantages for businesses and individuals looking to customize their apparel or accessories. By employing this method, users can achieve high-quality, long-lasting prints on various fabric types, including dark fabrics, thanks to recent advancements in dtf printing techniques. This versatility opens up a world of possibilities, allowing for the creation of custom dtf transfers that cater to diverse design needs and preferences.

Beyond aesthetic appeal, DTF transfer benefits extend to enhanced durability, ensuring your designs withstand regular wear and tear. The process involves precise application of ink directly onto the fabric, resulting in vibrant colors and intricate details that remain crisp over time. This makes custom dtf transfers an excellent choice for promoting brands, creating unique fashion statements, or personalizing gifts, enabling users to express their creativity effectively.

Strategies for Optimal Application: Achieving Desired Results

To maximize the benefits of DTF Transfer Benefits, strategic application is key. First, understand your skin type and needs; different dtf transfers cater to various concerns like hydration, anti-aging, or hyperpigmentation. Choose a product suited to your specific goals for optimal results.

Next, follow the instructions diligently. Proper preparation of the skin before application is essential. A clean, exfoliated canvas ensures better absorption of the active ingredients in the dtf transfer. Additionally, be consistent with use; regular applications over time will yield more noticeable improvements compared to sporadic use. Remember, patience is vital as results may vary based on individual factors.

Case Studies: Real-World Success Stories and Best Practices

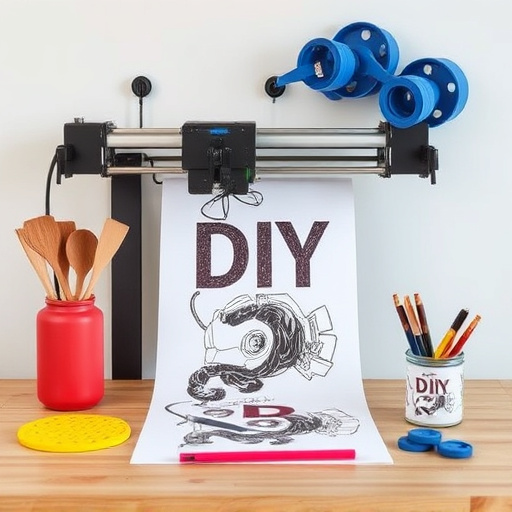

In the realm of garment customization, case studies offer tangible evidence of the effectiveness and versatility of DTF Transfer Benefits. Real-world success stories showcase how businesses and hobbyists alike have harnessed the power of custom DTF transfers to create unique, high-quality designs on a variety of garments. These stories often highlight specific best practices that contribute to optimal results, such as meticulous preparation of the substrate (e.g., cleaning and pre-treating fabrics), precise application techniques, and careful selection of heat press settings to avoid burn-out or smudging.

For instance, many successful case studies feature the use of custom sheets for heat pressing designs onto garments. These sheets allow for intricate detailing and vibrant colors, transforming ordinary clothing into expressive canvases. Heat press machines play a crucial role in this process, enabling precise temperature and pressure control to ensure that designs are permanently transferred without damaging the fabric. As a result, businesses have been able to create personalized apparel, from small-batch runs for niche markets to large-scale orders for popular brands, all while maintaining exceptional quality and customer satisfaction.

Applying DTF Transfer Benefits effectively requires a strategic approach, as highlighted in this article. By understanding the potential of DTF transfers and implementing best practices, individuals can achieve remarkable results. The strategies outlined, supported by real-world case studies, offer a roadmap for maximizing the advantages of DTF transfers. Embracing these techniques ensures that users not only unlock but also harness the full power of DTF Transfer Benefits, leading to efficient and successful outcomes.